Small parts / Others

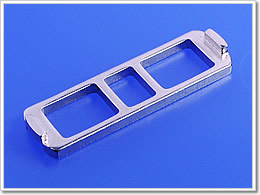

| Thickness | 10.00mm |

|---|---|

| Length | 100.00mm |

| Material | SS400P |

| Application | Distribution board switch |

| Features | This product is fabricated using a progressive die and has a protrusion. The edge width between the exterior form and the rectangular holes is narrow; and stepped punching is performed to prevent necking. |

| Thickness | 6.50mm |

|---|---|

| Length | 110.00mm |

| Material | SAPH440 |

| Application | Automobile oil pump cover |

| Features |

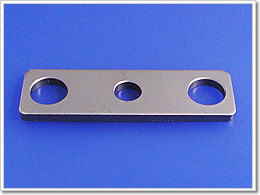

| Thickness | 2.40mm |

|---|---|

| Length | 26.40mm |

| Material | S55C |

| Application | Automobile seat belt part |

| Features | The pressing die for this part has movable punches in multiple rows to accommodate large production lots. A boss pitch precision of ±0.03 mm is ensured. |

| Thickness | 5.50mm |

|---|---|

| Length | 70.00mm |

| Material | SPHC |

| Application | Bicycle disc pad part |

| Features | The 20 mm diameter portion is coined to be concave. |

| Thickness | 4.00mm |

|---|---|

| Length | 80.00mm |

| Material | SPHC |

| Application | Medical equipment |

| Features |

| Thickness | 4.00mm |

|---|---|

| Length | 60.00mm |

| Material | S45C |

| Application | Two-wheeled vehicle engine part |

| Features |

| Thickness | 4.00mm |

|---|---|

| Length | φ37.10mm |

| Material | SP |

| Application | Automobile shock absorber part |

| Features | A perpendicular sheared surface is obtained using forming/punching technology. |

| Thickness | 3.20mm |

|---|---|

| Length | φ29.00mm |

| Material | SP |

| Application | Automobile shock absorber part |

| Features | A perpendicular sheared surface is obtained using forming/punching technology. |

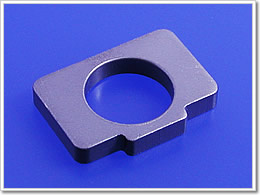

| Thickness | 3.00mm |

|---|---|

| Length | 30.00mm |

| Material | SPHC |

| Application | Lock part |

| Features | A 100% sheared surface is provided even when stamping a coined portion. |

| Thickness | 4.50mm |

|---|---|

| Length | φ50.00mm |

| Material | SS41 |

| Application | Pole guide |

| Features |

| Thickness | 4.00mm |

|---|---|

| Length | 27.00mm |

| Material | SPHC440 |

| Application | Automotive Tensioner Parts |

| Features |

| Thickness | 4.90mm |

|---|---|

| Length | 105.50mm |

| Material | SUS304 |

| Application | Two-wheeled vehicle part |

| Features | FB fabrication of SUS 304 achieves a precision of ±0.01 mm for the hole diameter and the dimensions. |

| Thickness | 8.00mm |

|---|---|

| Length | Height Dubbo: 8.00mm |

| Material | SPHC400 |

| Application | Automobile drum brake part |

| Features |

| Thickness | 3.60mm |

|---|---|

| Length | 20.00mm |

| Material | S45C |

| Application | Two-wheeled vehicle engine part |

| Features | High precision is required for the sheared surface and the surface roughness of the cross section. |

| Thickness | 5.00mm |

|---|---|

| Length | φ24.00mm |

| Material | SPCC |

| Application | Balancer |

| Features | The dimension of the surface stamping of the hole is very stringent. Measures are taken to blank without changing the dimension of the surface-stamped portion when blanking the exterior form. |

| Thickness | 3.60mm |

|---|---|

| Length | 51.60mm |

| Material | SPHC |

| Application | Personal computer part |

| Features | FB punching achieves an edge width of 30% of the plate thickness in one area, even though the general fabrication limit is 60% of the plate thickness. The fabrication conditions are extremely stringent. |

| Thickness | 4.00mm |

|---|---|

| Length | φ40.00mm |

| Material | SK5 |

| Application | Automobile engine part |

| Features | The oil supply to the cutting portions during punching is important for this part made of SK5; and oil is supplied directly inside the die. |

| Thickness | 4.00mm |

|---|---|

| Length | 102.00mm |

| Material | SPHC |

| Application | Automobile fuel tank reinforcing part |

| Features | The die is made of YXR3 to prevent damage of the die when making this slender product. |

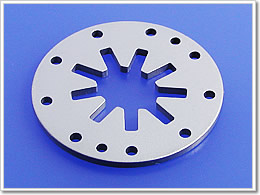

| Thickness | 8.00mm |

|---|---|

| Length | φ120.00mm |

| Material | S45C |

| Application | Automobile part |

| Features | Precision between the inner and outer diameters and a sheared surface are required. |

| Thickness | 6.00mm |

|---|---|

| Length | 65.00mm |

| Material | NP233 |

| Application | Automobile engine part (hub) |

| Features | Plastic formation to increase the thickness is performed inside a progressive FB die. |

| Thickness | 1.50mm |

|---|---|

| Length | 30.00mm |

| Material | PBSP-H |

| Application | Sensor part |

| Features | The small holes near the center are 1.25 mm in diameter which is less than the plate thickness. |

| Thickness | 1.95mm |

|---|---|

| Length | φ35.00mm |

| Material | 1%SiFe |

| Application | Center yoke |

| Features |

| Thickness | 2.00mm |

|---|---|

| Length | 30.00mm |

| Material | Al505-2S |

| Application | Electrical part |

| Features |

| Thickness | 6.50mm |

|---|---|

| Length | 97.00mm |

| Material | SP |

| Application | Automobile part |

| Features | Thickness-reduction forming is performed using progressive fabrication to make the step in the center hole. |

| Thickness | 6.00mm |

|---|---|

| Length | 156.00mm |

| Material | S45C |

| Application | Automatic loom |

| Features |

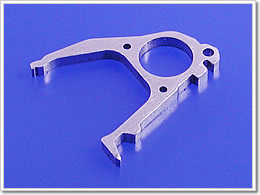

| Thickness | 6.00mm |

|---|---|

| Length | 61.00mm |

| Material | S45C |

| Application | Automatic loom |

| Features |

| Thickness | 6.00mm |

|---|---|

| Length | 80.00mm |

| Material | SAPH440 |

| Application | Automobile engine part |

| Features |

| Thickness | 8.00mm |

|---|---|

| Length | 93.00mm |

| Material | SCM435 |

| Application | Loom |

| Features |

| Thickness | 3.50mm |

|---|---|

| Length | φ43.00mm |

| Material | SPH440W |

| Application | Recliner seat part |

| Features |