HOME Technology

Technology Primary processing technology

Primary processing technology Fine-blanking working

Fine-blanking working

Fine-blanking (FB)

Each day, 900,000 parts having cross sections similar to those of machining are produced by 39 machines in Japan that range from 250 tons to a super-large machine of 1200 tons.

Considerable contributions include rationalization of the part finishing, improvement of the precision, and uniformity. This is a particularly powerful solution when the plate thickness is about 6 to 19 mm.

|

|

What is conventional punching using a normal press?

In normal stamping, the punching is performed by a combination of a punch and a die.

First, the punch descends; the punch contacts and pressurizes the material on the die; the material receives a bending force and deforms; then fracture occurs after a shearing phase; and the punching is completed prior to the punch passing through the material.

Therefore, there are disadvantages such as large rounding and burr, a large fractured surface, a small sheared surface, the cutting surface being not perpendicular to the material surface, the plane of the punched product being curved and not flat, etc. Secondary operations are necessary in many cases.

Features of fine blanking (FB)

Fine blanking (FB) began with the German Patent No. 371,004 by Fritz Schiess of Switzerland in 1923 and was developed to be fit for practical use in the subsequent 30 years.

FB fabrication can finish a part all at once by punching the material to be fabricated with high precision. Therefore, the outer frame that is necessary for normal stamping becomes unnecessary; and secondary operations such as reaming holes, milling, etc., also are unnecessary.

The method in which punching is performed by controlling the flow of the material of the shearing portion of the punched material is called fine blanking (FB).

Namely, a high compressive stress is caused to occur in the interior of the material, cracks are prevented by increasing the ductility of the material, and a beautiful sheared surface that is perpendicular and has no fracture is obtained by using a plate holder that has a knife edge-shaped V ring, a counter holder, and punches and dies that have extremely small clearances.

|

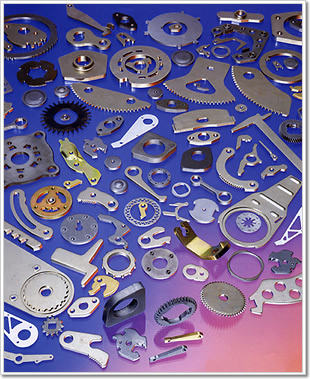

| (Line-up of products procesed by FB process) |